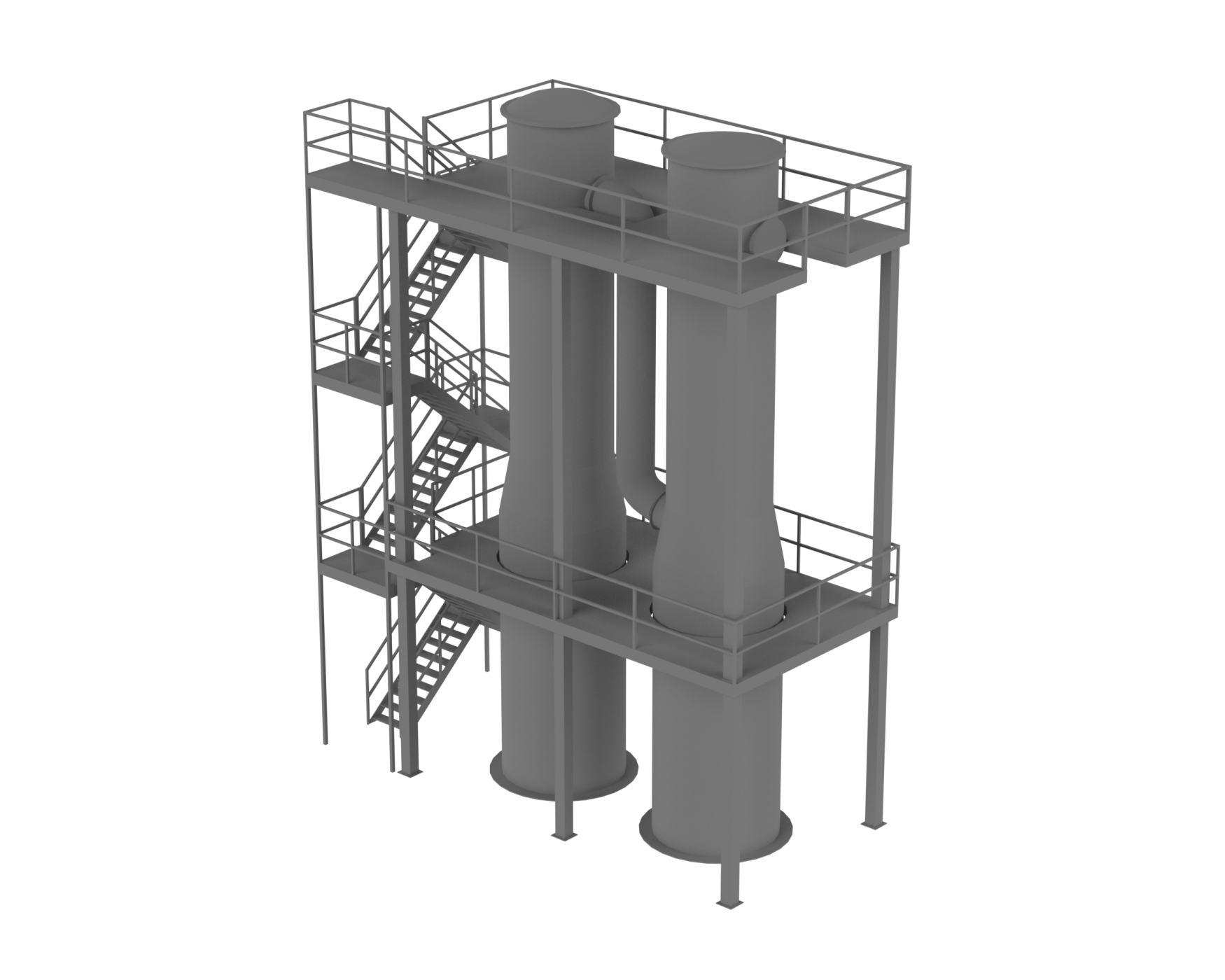

How does a falling film evaporator work?

A falling film evaporator is a vertically oriented shell and tube heat exchanger to concentrate solutions with different boiling point temperatures. Generally, the evaporation takes place inside the vertical pipes, but there are also applications where the process liquid evaporates outside the horizontal pipes. The evaporating process fluid flows downward in tubes by gravity in a continuous layer. The fluid will form a falling film along the sides of the tubes. To ensure the even distribution of the liquid in all pipes along which the solution falls, the liquid distributor must be carefully designed. In most cases, the heating medium is placed outside the pipes.

The heat transfer coefficients should be high to achieve an equally balanced heat transfer resistance. Commonly, condensing steam vapor is used as a heating medium. The separation of the liquid phase from the gas phase takes place inside the pipes in the case of internally evaporating liquids. During the falling film evaporation process, the downward velocity of the vapor increases, increasing the shear force of the liquid film, and thus also the speed of the solution. The high film speed of the thinner film results in an increasingly turbulent flow, which creates very high heat transfer coefficients. When mass flow is increased, the falling film is changing from laminar to turbulent.

Evaporators are perfect for waste heat recovery in multi-stage processes. It is ideal for heat-sensitive products like stick water from the rendering plants. Small average temperature differences between the heating medium and the steam vapor, make evaporation installation very efficient. The residence time of the liquid inside the machine is very short. Falling film evaporators can operate under vacuum pressure and are characterized by very low-pressure drops.

Evaporator fouling factor

The close contact of the liquid with the heating surface makes the evaporators sensitive to contamination from precipitating solids. To effectively self-clean the pipes, the low velocity of the inlet liquid is usually not sufficient. Therefore, falling film evaporators are used in clean, non-precipitating liquids. Chemical and most widely used method for cleaning of the falling film evaporator can be carried out by caustic soda.