Meal cooling machines

How does the cooling system work?

The main aim of the cooling system is to keep the temperature of a structure or equipment from exceeding the limits imposed by safety and performance needs. In the event of overheating, the oil in the mechanical transmission loses its lubricating properties, and the fluid in the hydraulic clutch or converter escapes under the pressure generated.

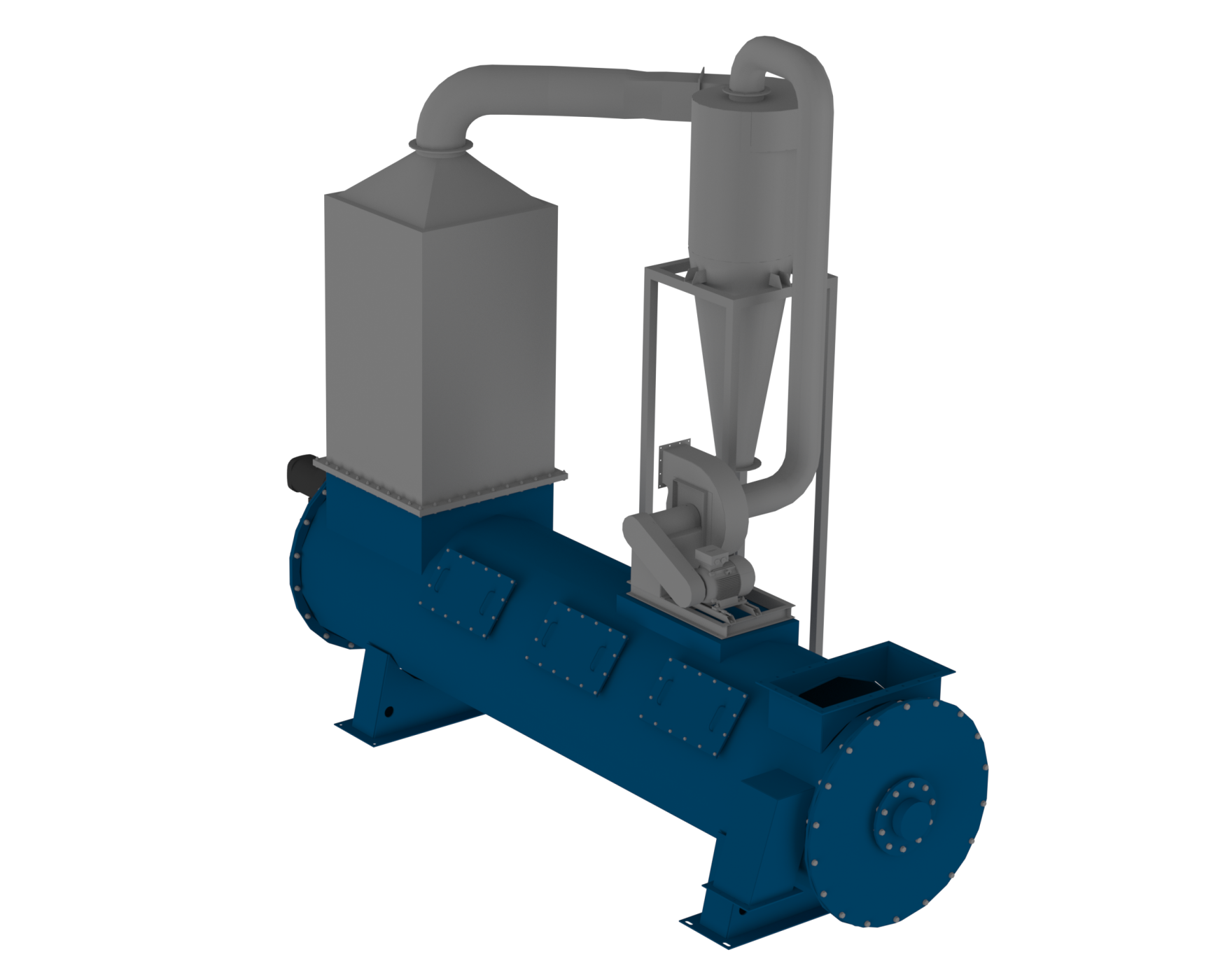

Cooling solution for rendering plant

An industrial meal cooler is a machine that is cooling meal products after the drying process. It can be applied to fish meal, feather meal, poultry meal, and to the other different types of the meal. An industrial cooling machine is a machine that can be used in dry and wet temperature rendering plants. The cooling machine is utilizing ambient temperature to cool down the meal, which temperature is very high after the drying process and can even reach 110 °C. Therefore, a meal cooler works best when the temperature outside is relatively low. The cooled air should be as cold as possible, and it should be connected with some cooling system if such a system is installed in the plant.

Thermal control of the meal is very important because higher temperatures increase the risk of meal contamination by bacteria due to the condensation process. A meal cooler seems like a simple machine, but it is not, because the cooling process is quite complex. There is a need to take into consideration many factors which are affecting the cooling process like the temperature of cold air flow, meal composition, antioxidant chemistry, and powder volatility.

An industrial centrifugal fan is installed with a bag filter or cyclone, which is responsible for the separation of meal dust from cooling air. Cyclone separators are much, much cheaper than bag filers, but using them result in more meal flowing in the air. Bag filters are designed as self-cleaning devices. They provide better meal separation performance in comparison with cyclone separators. TG-Machines will help to find the best suitable solution for cooling your meal product. To look at more details and features of our equipment, please scroll down and open the meal cooler machine tab.