Pressure cooker, sterilization, and hydrolysis

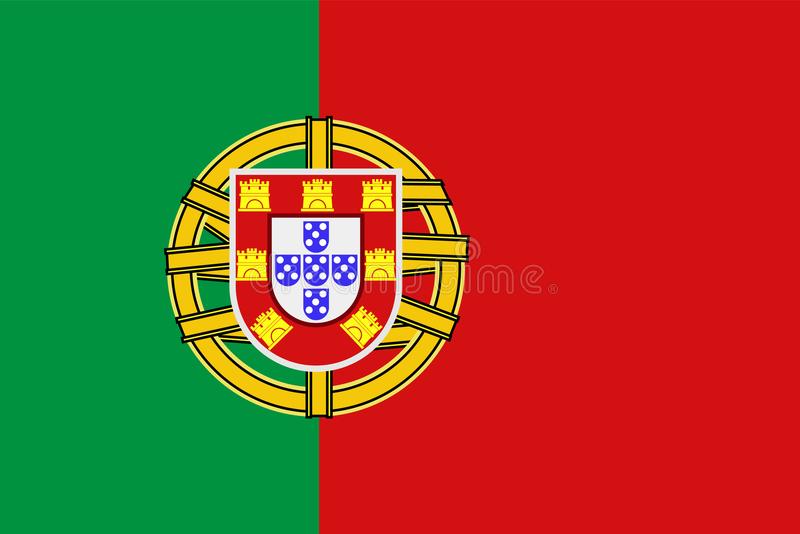

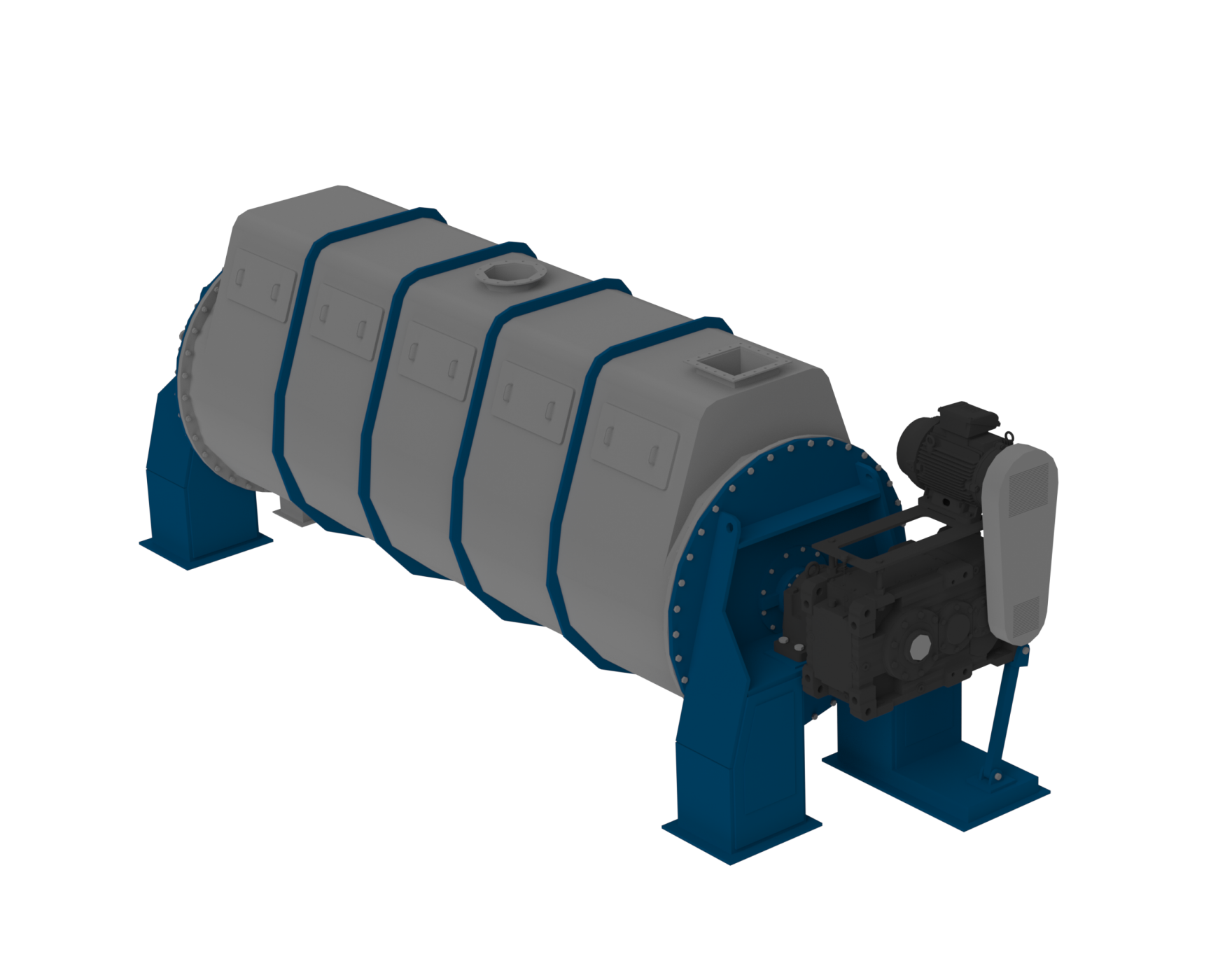

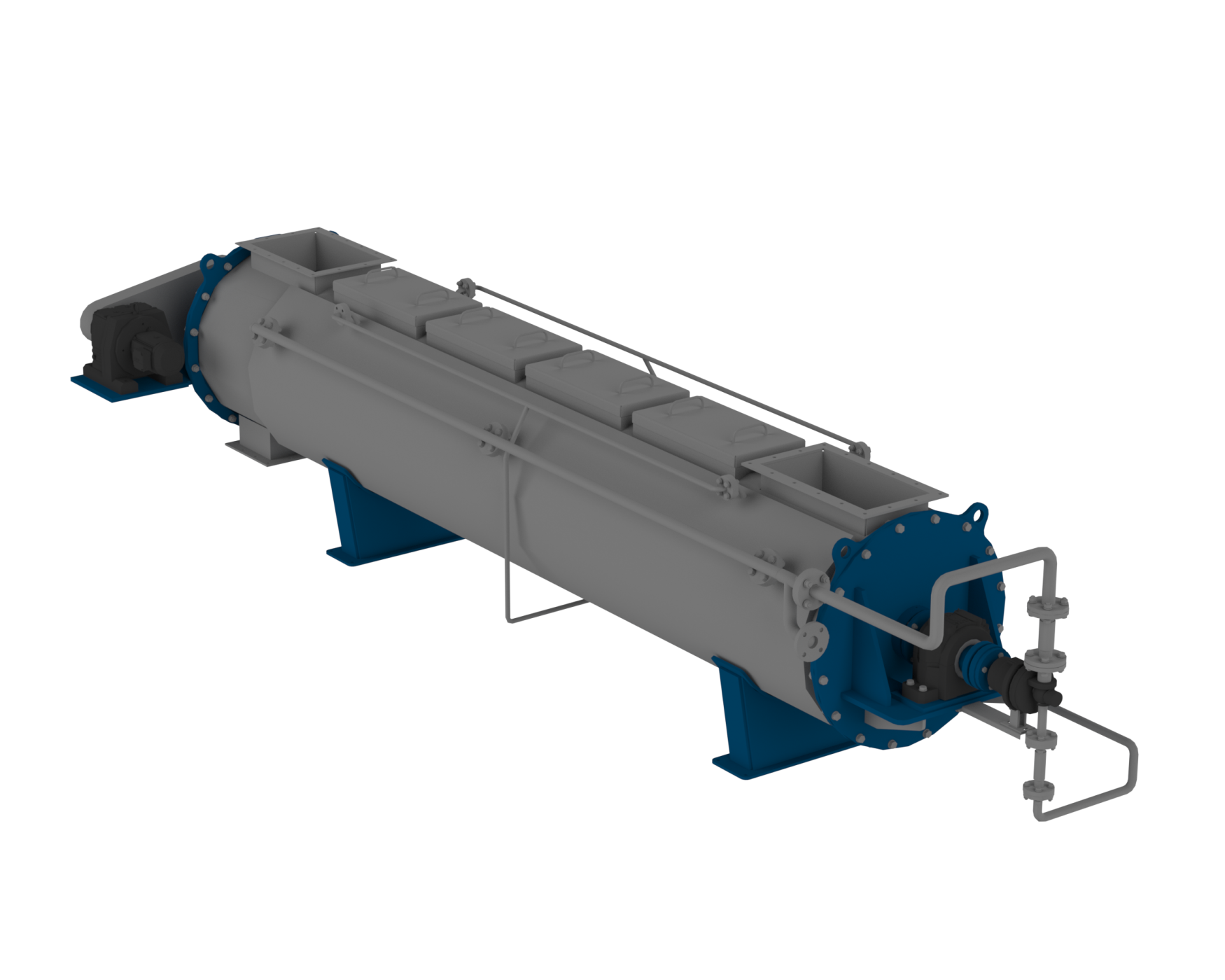

Processing of animal by-products requires cooking and sterilizing equipment to ensure the correct transfer of heat to the raw material. Autoclave and pressure cookers solutions are available for animal and poultry by-products rendering. Suitable pressure and temperature in sterilizer allow producing high-quality protein products from slaughterhouse raw material. TG-Machines offer three types of high-pressure equipment for cooking and sterilization processing: rendering disc cooker, batch cooker, and rendering continuous cooker.

Raw materials such as meat, carcass, poultry, feathers, blood, and fat are converted into proteins, oil, and minerals. Animal by-products are valuable on the market, which needs energy-efficient automated machines important for the process economy and for cost optimization. When a customer decides to buy a batch cooker or other machine, the payback calculations are very significant and must be taken into account.

What is the batch sterilization process?

Batch sterilization is the reduction of contaminating organisms by heating the vessel. The entire volume of the medium is sterilized at once by thermal or radiation techniques. The temperature is raised until it reaches the sterilization temperature at which it is maintained for a certain time.

What is the process of sterilization?

Sterilization can be achieved by a variety of means, including heat, irradiation, chemicals, high pressure, and filtration. Sterilization differs from disinfection, sanitation, and pasteurization in that these methods reduce, rather than eliminate, all life forms and biological agents present.

Which sterilization method is the best?

In most laboratories, autoclaving is the preferred method of laboratory sterilization: using pressurized steam to heat the sterilized material. It is a very effective method that kills all microbes, spores, and viruses, although for some specific insects particularly high temperatures or incubation times are required.

Batch cooker sterilization

Batch cooker is the best pressure cooker for sterilization in the rendering industry. It is a direct injection steam vessel that rotates and mixes the material. In this machine, at a specific pressure and temperature, a complete sterilization process takes place. Raw materials like wet feathers, raw blood, meat offal with bones, and poultry offal can be cooked and sterilized.